✨ Bespoke Industrial PC Your Wise Choice! View product catalog

With the rapid development of industry, increasingly complex application environments are placing higher demands on computer performance. Wisemaker has launched industrial computers with higher performance configurations and superior cooling solutions to meet these application needs! Today’s computers are used in a wide range of complex scenarios, such as machine shops, laundry production lines, woodworking factories, automated production workshops, traffic equipment control, AI visual recognition, and IoT edge computing. These applications require higher-performance CPU configurations, which leads to a need for upgraded computer cooling solutions. Considering the dusty environments and the need for low maintenance costs over time, natural cooling is the optimal choice in computer design. As a result, fanless cooling solutions are being applied more widely in industrial computers.

A natural cooling solution needs to take into account three key elements: thermal conduction, convection, and thermal radiation. Good thermal conduction materials efficiently transfer heat from the CPU to the heat sink. Excellent heat dissipation materials combined with proper surface treatments provide a high convection coefficient and thermal emissivity, allowing heat to be rapidly released into the surrounding environment and achieving efficient cooling performance. In addressing these three key elements of cooling, it is important to first understand the characteristic parameters, processing methods, and surface treatments of commonly used materials:

Thermal conductivity of materials:

| Common materials | ADC12 | AL6063 | Red copper | Heat pipe |

| Thermal conductivity coefficient | 93 W/(m·K) | 201 W/(m·K) | 390 W/(m·K) | 5000 W/(m·K) |

Note: Thermal conduction is the process by which heat is transferred from the higher-temperature part to the lower-temperature part within an object or between objects in direct contact.

Natural convection heat transfer coefficient:

| Common materials | AL6063 | ADC12 |

| Natural convection heat transfer coefficient | 15~20 W/(m²·K) | 5~10 W/(m²·K) |

| Manufacturing process | Extrusion molding | Die casting molding |

| Surface treatment | Sandblasting anodizing | Electrostatic powder coating |

| Manufacturing cost | High | Low |

Notes: The heat transfer coefficient is the ratio used to calculate

the amount of heat transferred between a fluid and a solid surface.

Anodizing forms an oxide film on the surface of the workpiece

through an electrolytic reaction; the film has a porous honeycomb structure

with very small pores.

Powder coating forms a polyester layer on the surface of the workpiece through electrostatic adsorption.

| Surface Treatment | Anodizing | Powder Coating |

| Emissivity (Blackness) | 0.852 | 0.852 |

| Thermal Conductivity | Relatively high | Relatively low |

| Overall Heat Dissipation Capability | Radiation + Conduction Enhanced Cooling | Mainly relies on radiation cooling |

Thermal emissivity coefficient:

| Common materials | AL6063 + sandblasted anodizing | ADC12 + electrostatic powder coating |

| Thermal emissivity coefficient | ≥0.85 | 0.75~0.87 |

Note: Thermal radiation is a physical phenomenon in which a heat-emitting body transfers its temperature energy outward in the form of electromagnetic waves.

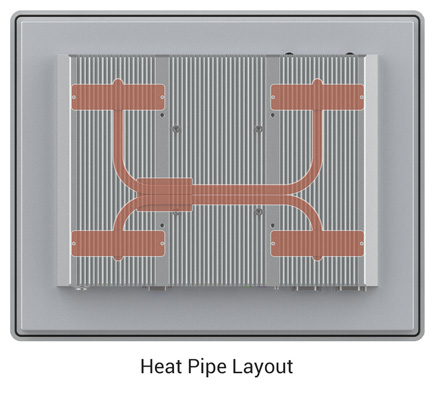

Based on the above data, the initial design selects red copper combined

with heat pipes as the thermal conduction materials, AL6063 as the extruded fin

profile material, and chooses sandblasted anodizing as the surface treatment.

Heat pipe +Alu cooling housing:

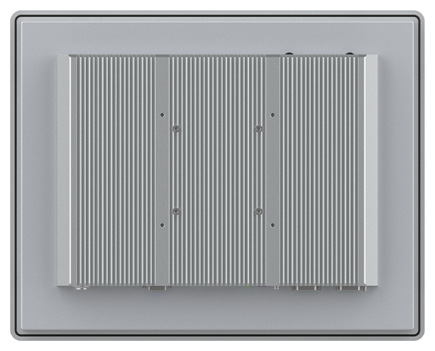

1. Fin Heat Dissipation: The AL6063 extruded profile, width and height dimensions are 292 × 210 mm, with fins arranged longitudinally to promote airflow and effectively carry away heat.

2. Heat Pipe Thermal Conduction: Heat pipes combined with copper plates are evenly and symmetrically laid on the back of the finned heat sink, efficiently transferring CPU heat to the heat sink. This converts a point heat source into an area heat source, improving thermal conduction efficiency.

3. Surface Treatment:

After processing the profile, the heat sink surface is first sandblasted and

then anodized. This treatment enhances the appearance and wear resistance,

provides oxidation and corrosion resistance, and improves the thermal radiation

and heat dissipation performance of the heat sink.

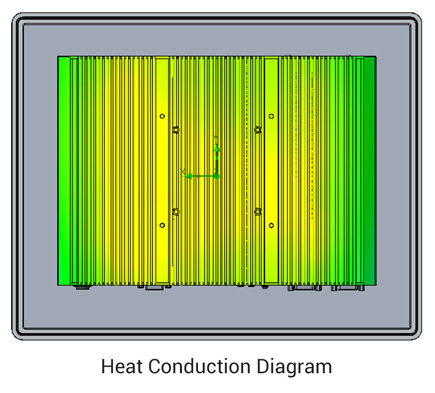

Simulate heat conduction through

thermal simulation, it is clearly visible that the temperature difference

across the heat sink area is minimal;

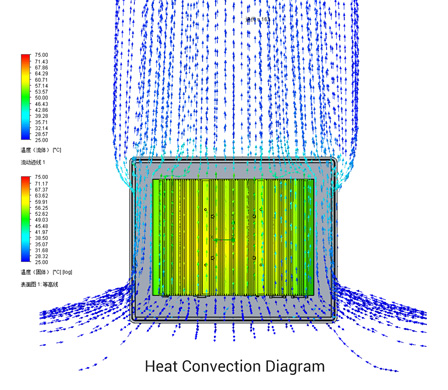

The simulation conditions assume no wind, with the heat sink exchanging heat with the air through natural convection. Due to gravity, the air heated on the surface of the heat sink rises upward, while cooler air from below and the sides flows longitudinally along the fins to replenish it, creating an upward airflow. Thermal simulation of this convection process clearly shows the temperature changes of the air as it passes over the heat sink.

To

further verify the effectiveness of the cooling design, the heat sink was

manufactured according to the design scheme, and a prototype was assembled for

physical testing.

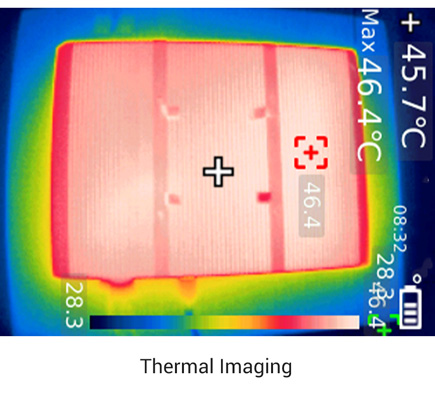

Using a professional thermal imaging tester, the real-world cooling effect can be visually confirmed to be consistent with the simulated cooling results.

Through aging test comparisons, the heat sink temperature dropped by 15%, the CPU temperature decreased by 13%, and performance improved by 15%. It is clearly observed that for fanless cooling solutions in industrial computers, using large-area heat pipe layout for thermal conduction transforms a point heat source into an area heat source, efficiently transferring heat to the heat sink. After anodizing the surface of the high-quality AL6063 extruded fins, thermal radiation efficiency is significantly improved, resulting in better overall cooling performance. The overall temperature reduction of the industrial computer allows the CPU to operate at strong performance while ensuring stable operation and long service life of the entire system.

In

summary, our thorough thermal simulations and innovative cooling design ensure

efficient heat dissipation and reliable performance in demanding industrial

environments.

Wisemaker

high-performance industrial panel PCs feature an advanced fanless

cooling solution that utilizes heat pipe thermal conduction

combined with a large-area extruded fin heat sink design. This

innovative cooling system efficiently transfers CPU heat through natural

convection and enhanced thermal radiation efficiency, ensuring

reliable operation even in harsh, dusty industrial environments.

The sandblasted

anodizing surface on the extruded fins not only improves heat

dissipation but also provides excellent wear resistance and corrosion

protection, contributing to the device’s stable and long service life.

With a robust fanless design and high effective heat dissipation, our panel PCs

ensure reliable operation and excellent performance in challenging industrial

environments.